Best Glue for Rubber – A Guide to Selecting an Adhesive for Rubber

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

When you think of glue, you might not consider something like an adhesive for rubber. This is because it is still not an extremely common thing, and many times, broken or damaged items are simply thrown away or replaced without repairing. However, if you are looking for a good rubber glue, then read further to discover different types of rubber adhesive, the various applications, and the best rubber glue on the market.

Table of Contents

Types of Rubber Glue

Rubber is classed as a polymer, which is a chemical compound that has larger molecules that are made up of many of the same types of smaller molecules. Natural rubber is obtained from plants, however, today you also get synthetically produced rubber. There are many rubber items you can find in and around the house, but rubber is also used in various industries that include some of the following:

- Car and bicycle tires

- O-ring seals

- Printing rollers and other industry rollers

- Clothing and shoes, such as rubber soles or raincoats

- Mattresses and cushions

- Bathtub plug

- Hot water bottles

- Backing on carpets

- Diving equipment

- Vibration dampeners

- Windscreen wipers

- Animal toys

- Various applications in the medical field

As you can see, rubber is used almost everywhere particularly because of its strength and flexibility. Synthetic rubber is produced by a process called vulcanization, where the rubber is placed under extreme pressure and heat while sulfur is added to the mix. This creates a cross-link, and the rubber becomes elastic and also exhibits other beneficial properties. The method was established by Charles Goodyear in the 1830s.

Soft versus Hard Rubber

Rubber can be classified into two main groups, being soft rubber and hard rubber. Soft rubber contains five to ten percent sulfur and is extremely elastic, while hard rubber is not elastic and contains at least 30 to 50 percent sulfur. From these two main categories, there are many grades of rubber as well as blended varieties. For example, foam rubber, Santoprene, Buna-N, and Elastane. Foam rubber is very popular in the hobby industry. Below are the various types of rubber you get today.

- Natural rubber, which is the most commonly used and can be found in things like the backing of carpets.

- EPDM Rubber (ethylene propylene diene monomer), a synthetic rubber that is used in things like automotive hoses.

- Silicone rubber, which has excellent heat-resistant properties and is used in things like cookware and other kitchen items, as O-rings, in medical devices, as well as in prosthetics.

- Butyl rubber is flexible and can be found in items like inner tubes and seals.

- Nitrile rubber is commonly used in many applications such as O-rings, conveyor belts, printing rollers, and lots more.

- Polyurethane rubber is used for molds, seals, gaskets, and other hard plastic parts.

When to Use a Rubber Adhesive

As mentioned, rubber is used a lot around the house and in industry, and therefore, rubber glue has quite a few applications. An adhesive for rubber usually has an elastic consistency and bonds easily with rubber. It can seal any gaps or cracks in the rubber as well, which makes rubber repairs quite easy.

Rubber glue can offer protection and improved strength in a variety of ways. For example, glue for rubber shoes, or tires, and helping mend hoses or inflatable boats.

The best rubber glue is resistant to temperature and water, so it will work perfectly for hoses and other rubber items exposed to these elements. Having an emergency rubber repair kit handy when in an inflatable boat is a good idea and should be something you have on your supply list. Rubber glue is not only great for those quick fixes but is also used to bond different materials. For example, the foam rubber we mentioned earlier can easily be bonded to other materials with a good rubber adhesive.

Model making is also an area where rubber glue comes in handy. You can apply the rubber adhesive with precision and the results are permanent. Thermoplastic elastomers (TPE Glue), also referred to as thermoplastic rubbers, have the characteristics of rubber but can be reprocessed, remolded, and recycled. Products made from TPE glue usually have a smooth and non-slip surface, which makes it difficult to bond. However, rubber adhesives can still be used as they have good wetting properties and work well on this type of material.

Properties of Rubber Glue

The best glue for rubber that provides a durable and permanent bond might be difficult to choose, as it often needs to be compatible with the rubber compound and for its particular use. However, you do get many rubber adhesives that can be used for general purposes and will form a strong bond. Two popular and well-known glue varieties for general purposes include your superglue for rubber and the two-component adhesive options.

These options are not only suited for rubber-to-rubber bonds but also bond well to other materials. For example, bonding rubber to wood or metal.

There are also all-purpose adhesives available that should be able to bond rubber to various materials, but the bond formed will not be as effective as a particular rubber adhesive. Also, these types of adhesives contain solvents, and their flash-off time must be considered when using them. You can also purchase these types of adhesives as an aerosol spray.

Other types of glue include hot melt adhesives, which are thermoplastic resins, and these soften or melt when heated. These adhesives can be used to bond a variety of materials and are especially effective when used to bond latex or rubber to metal. You also have water-based dispersion adhesives that provide temperature and water resistance as well as an excellent bond.

When considering any adhesive, the main property you are looking for is its bonding strength, as you want your repair job to last a long time. However, while the best glue for rubber has many benefits, there are also a few disadvantages. This is why rubber glue must be used correctly and with caution, but if all precautions are followed, the rubber adhesive will form a strong and effective bond that should last. Let us have a look at the main pros and cons of rubber adhesives.

PROS

- Extremely good bonding qualities

- Flexible and elastic properties allow it to adapt to various stressors

- Excellent sealing properties

- High resistance to wear and tear and other external influences

CONS

- Include harmful substances that can be detrimental to the environment

- May give off toxic and flammable fumes

- Poses a health risk

Best Glue for Rubber

Rubber glue might not be the most common product when compared to other types of glue, but there are still a few options available. So, let us have a look at what alternatives you can use as the best adhesive for rubber.

Best All-Purpose Glue for Rubber: Superglue

A great alternative to rubber glue is an all-purpose glue or superglue. Superglue is a popular and well-known adhesive that dries quickly while forming a strong bond. Superglue is easy to use and comes in a handy tube that can provide precise application. The fast drying time can be an advantage, but it can also be a disadvantage. This is because it is more for smaller applications – larger surfaces are not possible. When bonding rubber with superglue, to make the process more effective, you can lightly roughen the bonding surface. This should provide an even better and stronger bond.

Best Superglue: GORILLA Super Glue Gel

This product comes in various tube sizes and has quite a few advantages. This super glue for rubber offers excellent bonding properties. The glue is highly flexible because it contains micro-rubber particles and is solvent-free. You can use the superglue on a variety of surfaces including leather, wood, and other porous surfaces. The gel formula also allows you to apply it to vertical surfaces. The glue is perfect for those smaller repair jobs and will provide you with a strong and permanent bond.

- No run control gel formula that is great for use on vertical surfaces

- Gorilla tough anti-clog cap helps keep glue from drying out

- Specially formulated for increased impact resistance and strength

PROS

- Provides vibration-dampening properties and is shock-resistant

- Resistant to adverse weather conditions

- Waterproof

- Can be used outdoors

- Gel formula does not drip

- Easy to use

- Bonds porous materials like wood

CONS

- Drying times can differ for different materials

- Gives off fumes that can irritate the lungs, so wearing protective eyewear and a mask is advisable

Best Hard Rubber Adhesive: Epoxy Resin Glue

One method of creating an extremely strong bond is by using a two-component adhesive. This process is not difficult – the adhesive comes in two parts which need to be combined in order to form a reaction. The substance will then cure, forming a strong and durable bond. We recommend Gorilla’s two-component adhesive for your rubber repairs.

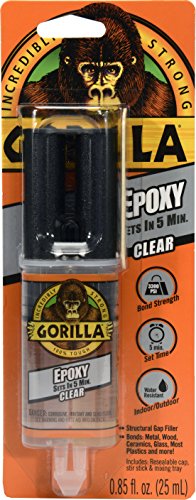

Best Two-Component Adhesive: GORILLA

This Gorilla two-part epoxy adhesive is quite versatile and can easily glue different materials, such as rubber to wood or metal. This type of adhesive is perfect for those difficult repair jobs that require a more durable bond. The adhesive will dry clear, is easy to use, and can be used for multiple applications.

- Strong, permanent, fast, and gap-filling glue for multiple surfaces

- Best for tough repairs requiring a durable bond and solvent resistance

- Dries clear, sets within 5 minutes, and is ideal for clean, easy finishing

PROS

- Can be applied to a variety of surfaces

- Adhesive can be painted over once cured

- Resistant to water and temperature changes

- Easy-to-use double-chamber syringe application

- Strong and durable bond

- Can be used for heavy loads

CONS

- Curing time is a minimum of 24 hours

- Some common product faults include half-filled syringe units

How to Use Rubber Glue

Applying adhesive for rubber is easy – anybody can do it. However, to make sure the glue is right for the job, first test a small amount on the material you wish to bond. Once you have determined that it is okay to use, you can go ahead and apply it to the rest of the surface. You should also read the product specifications before purchasing in order to make sure that you are getting the correct adhesive for your purposes and that it is designed to bond to your specific materials.

Preparation

The first step in achieving a strong bond is to make sure the surface is clean. All dirt, dust, and grease should be removed. Consider using a nitro thinner for this purpose. You can then lightly roughen the surface using some sandpaper. This will provide more of a surface for the adhesive to stick to and improves the strength of the bond.

On more difficult surfaces like metal, you can also add a primer. The primer is considered a bonding agent and will improve the adhesive properties of the glue. To get the best outcome, the surface should be absolutely dry before doing this.

Application of Rubber Glue

You can now commence with applying the adhesive evenly over the surface. You can use a brush or spatula for this purpose. Try not to let any glue get onto your skin and make sure that you work in a well-ventilated area. When applying an adhesive that contains solvents, take note of the flash-off time. This should be around 10 minutes and you can check up on this by reading the product directions. Once this time has passed, you can then place the two surface materials together to bond them.

Curing Time

Once the adhesive has been applied, it can take up to 24 hours to fully cure. This can vary, as it will also depend on the surrounding humidity and temperature. If in doubt as to how long to leave the bonding process, simply give it a little more time to make sure. The elasticity of the rubber glue will change as it dries, becoming less and less elastic. Once it has fully dried or cured, you can then mechanically process it further if needed.

How to Apply Rubber Glue to Wood

Again, the first step is to make sure the surface is clean. Take a dry cloth and wipe both the wood and rubber surfaces to get rid of any dirt and dust. Take your chosen rubber adhesive that should be temperature and water-resistant and apply it to the wood surface. Take the rubber material and place it onto the covered wood surface and hold it securely in place. Hold for about one minute until the adhesive has dried. You should work in a well-ventilated area and once you have glued the items together, keep this in the same area for about an hour. Wait until the adhesive has dried completely before you handle the item.

When it comes to using an adhesive for rubber and bonding it to various materials, it should not be difficult if you choose the correct adhesive. Also, preparation and making sure the surface is clean before you begin is important. In cases of metal surfaces, adding a primer is also essential to forming a strong bond. We hope that this article has helped you understand and select the best glue for rubber!

Frequently Asked Questions

Can You Use Hot Glue on Rubber?

Yes, hot glue can work on some rubber types, however, it might not work so great on certain rubbers that have an elevated oil content or those that contain plasticizers. Also, using hot glue on plastics like polypropylene and polyethylene will not work and the bond formed will not be strong enough.

How Do You Find Out if a Material Is PVC or Rubber?

You can take a small sample of your material, hold it, and place it over a burning lighter. If you notice that the material starts to smell a bit like burnt hair, it is rubber. On the other hand, if you notice the material begin to burn and become sticky or melt, it is PVC.

Is It Possible to Glue Metal and Rubber Together?

Yes, but you will need to make sure that all surfaces are clean and free from dirt. Lightly roughen the surfaces with sandpaper and then apply an appropriate primer. This helps to improve the adhesive qualities. Apply your chosen rubber adhesive, place the items together, hold and wait for it to dry thoroughly.

Can You Remove a Rubber Adhesive?

While the adhesive is still wet, you can remove the materials and wash them with some soapy water. If the adhesive has hardened, you can try using some white spirits or acetone to remove it. Otherwise, if the adhesive has hardened on a hard object, you may have to scrape it off.

Is It Possible to Use Adhesive on Latex?

Latex material can be challenging to work with, as any adhesive you use should not have any solvents or set too hard. Using the wrong type of glue can cause a weak bond or deform the latex material. You will need to use a specially formulated adhesive for latex.

Is There an Alternative to Rubber Adhesive?

Yes, there are alternatives to rubber glue, one being superglue and the other being a two-component adhesive. Super glue is perfect for smaller repair jobs.