Best Epoxy for Aluminum – How to Bond and Repair Aluminum

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

Aluminum is a popular metal as it is strong, lightweight, and has other desirable properties, which makes it very useful. However, aluminum can break, and this is where a good aluminum epoxy can be beneficial. Aluminum epoxy filler can be used to help fill cracks or patch a leaky pipe. You do not have to resort to welding or soldering the metal pieces. Aluminum epoxy makes the job easier and faster. To make things even easier, we will help you to choose the best epoxy for aluminum.

Table of Contents

What Is Aluminum Epoxy?

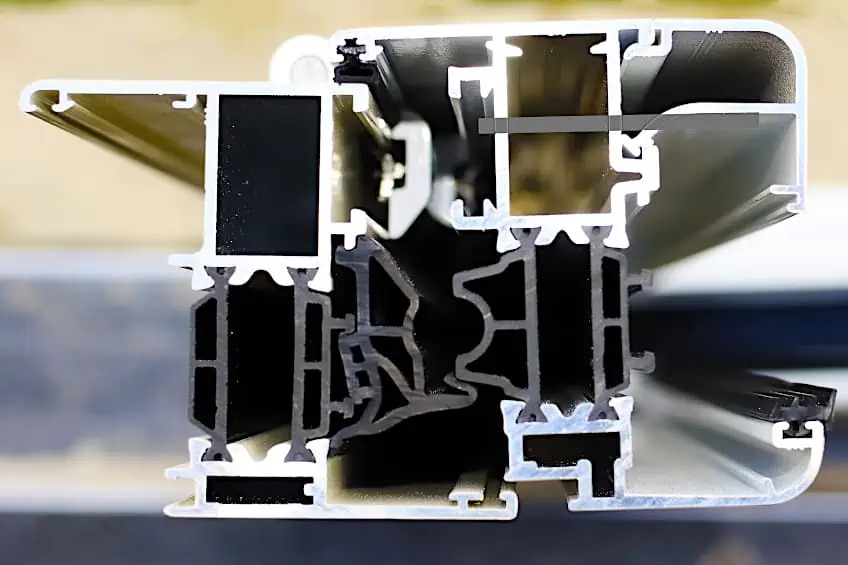

Firstly, aluminum is a lightweight metal and is utilized in many commercial and industrial purposes as well as in construction. The metal has many properties that make it perfect to use for these purposes. A few of these properties include strength, conductive properties, it is resistant to corrosion, malleable, and it is also affordable. You should be able to find aluminum in many everyday places, for example, cans, window frames, in electrical power lines, and forms part of cars as well as airplane parts to name just a few.

Aluminum is strong, but, as with all things, it can be damaged, and instead of replacing or throwing away the damaged or broken piece of metal, the next best option is to use an adhesive. There are many strong adhesives you can buy that can glue metal. However, aluminum epoxy can be considered one of the stronger adhesives for metal.

Epoxy usually consists of two parts, the epoxy resin, and hardener. These two components then have to be mixed before application and then allowed to cure. The final result is a hard and strong bond that should be able to withstand high forces and temperatures. Also, many epoxies provide water-resistant properties, which makes them great for plumbing or boat issues. Many of the epoxy products will also work well on other types of metals and even other surfaces, which makes them quite versatile.

How to Make the Best Choice When Buying Aluminum Epoxy

There are many products available that provide adhesive properties for metal. So, choosing the best epoxy for aluminum can be slightly challenging if you do not know what to look for. Below are some recommended factors to consider when going out to purchase your aluminum epoxy.

How Is the Epoxy Going to Be Used?

Epoxy does not only come in a two-part liquid form, but it can also come in a putty form. So, you will need to choose the epoxy that best suits your project. The specific repair you need to do should dictate what type of epoxy can be used. Small applications around the home can easily be repaired with a two-part liquid epoxy that comes with syringe applicators.

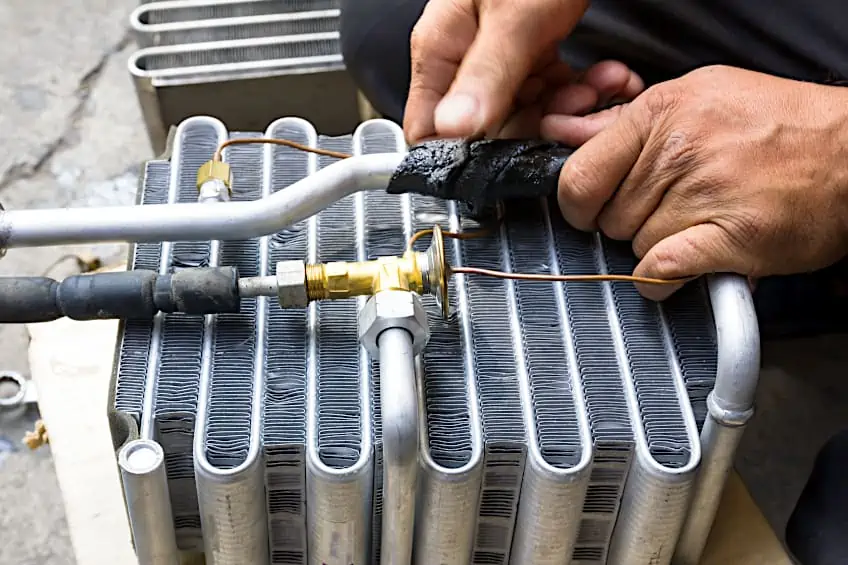

When it comes to more substantial applications, like fixing a boat hull, you require an epoxy that you can apply by using a brush or roller, which is best for a larger surface. This type of epoxy also needs to be water-resistant, which is also the case for plumbing issues. If you want to repair valves or pipes, a putty epoxy is the best option to mold around fittings.

You also might need an epoxy that can resist high temperatures, for example, in repairing automotive parts. The location of the repair can also play a role in the type of epoxy used. For example, if the repair needs to be done on a vertical surface or overhead, an epoxy putty might be recommended so it does not run all over the place before it is allowed to cure.

Flexibility and Strength

The epoxy should be able to withstand certain forces, which is also known as tensile strength. In other words, how long can the epoxy bond last when it is being pulled and pushed around. You should be able to find out an epoxy tensile strength on the label, the number should be around 1000 PSI, which is the general strength of a good epoxy for most applications. Some of the stronger epoxies can go up to 3000 PSI or even more. The stronger epoxies should be used in areas where there will be a lot of stress, for example, a boat or a car.

Resistance to Extreme Temperatures

Aluminum epoxy should be able to withstand high temperatures for various applications. Most epoxy products, in general, can withstand temperatures ranging from about 200 degrees Fahrenheit to over 500 degrees Fahrenheit. Temperature is also important for properly curing epoxy, and this should be stated on the product label, along with how much heat the epoxy can withstand.

Toxicity Levels

Most epoxy products should not be harmful to the environment, but they can still pose a health risk if used incorrectly. Each time you use epoxy, you should read the instructions provided that show you how to use the epoxy. Epoxy can irritate the skin and also release volatile organic compounds (VOCs). So, to work safely with epoxy, protective items should be worn. This should include gloves, a mask, as well as protective eyewear. Working in a space where there is proper air circulation is also important. The epoxy products should also be stored properly, usually in a dark and cool room that is not accessible to kids and pets.

Resistance to Water

There are some cases where the epoxy will need to be water-resistant. For example, repairing boats or plumbing fixtures. You need to look for an epoxy product that can be exposed to water and the elements. When applying most liquid epoxies, the surface needs to be dry. However, once fully cured it becomes water-resistant. Epoxy putties that are waterproof can be used for plumbing repairs. Some of these putty epoxies will also cure underneath the water.

Epoxy Drying Time

Many epoxy products have a time in which to dry and cure. The dry time is usually how long the epoxy takes to form a bond; however, the curing time is when the bond is at maximum strength. The drying time can be important for things like repairs done outside, where the jobs need to be done quickly.

Dry and cure times will be provided on product packaging as these can vary considerably. Some epoxies dry in a few seconds, while others may take hours to fully cure. This dry time can be a deciding factor on what type of epoxy you choose. Many of the epoxy products may dry to a white or gray finish, while others are transparent. If the bond is going to be visible, consider what would look better. Some epoxies can also be sanded and painted, so always check for this on the label.

Versatility of the Epoxy

Some epoxies are more versatile, so you should check to see if the product you choose can be used on a variety of surfaces or if it will work for your type of application. Some epoxies can be applied to metal, wood, plastic, concrete, and more. Some epoxies can also be molded, painted, sanded, and drilled. If you are using an aluminum epoxy around the house, a versatile product would be great for all kinds of repairs.

Epoxy Application

Generally, epoxy comes in two liquid components that must be mixed before you apply it. These two components must be combined, or the epoxy will not harden. An application can involve using a stick or some already come in a syringe-type applicator for smaller applications. The putty also comes in two parts, which need to be mixed and kneaded before application, and is usually simply applied by hand. When it comes to large surfaces that need repairs, you can use a paintbrush for better application.

When selecting an epoxy you need to be clear on whether the product will be used indoors or outdoors, as some types of epoxy degrade under UV. For this reason exterior grade epoxy is manufactured differently to epoxy meant for interior use. Choose a product that is more durable and resistant to water and environmental factors if the repairs are done outside. Many of the outdoor epoxies can also be used inside, but never the other way around.

Cost of the Epoxy

For some, this is an important factor to consider. However, most epoxies are affordable, some brands might be more expensive than others. Sometimes, if you purchase in larger quantities, it can also work out a bit cheaper. So, when comparing larger amounts to the smaller tubes, these can seem more expensive. However, you might only need a small amount, and buying larger quantities is not an option.

Best Epoxy for Aluminum

Now that you have an understanding of what to look for when purchasing an aluminum epoxy filler, you then need to decide on what brand or product to choose. There are quite a few popular and well-known brands including jb weld aluminum and Gorilla. Let us take a peek at a few of the epoxy products from these brands.

Best Aluminum Epoxy Putty: J-B WELD SteelStik Steel Reinforced Epoxy Putty Stick

The J-B Weld Epoxy Putty Stick is a quality adhesive that is an extremely popular product. This two-part epoxy putty contains powdered steel, which reinforces the bonds it makes, creating a very strong adhesive. This also allows the putty to bond with the aluminum surface a lot easier. Mixing the two components is simple, combine the same amounts of each component and mix. Then you can simply use this and apply it to the chosen surface.

After you have applied it, the putty will dry in five minutes and will fully cure in about an hour, and dries to a gray color. The epoxy is rust-resistant, chemical resistant, and can endure temperatures up to 350 degrees Fahrenheit (176.6 degrees Celsius). The tensile strength is also quite good at 900 PSI. The dried putty can also be sanded, drilled, painted, and shaped to suit your needs. Besides aluminum, the epoxy can also be applied to other surfaces including copper, bronze, fiberglass, stainless steel, iron, plastic, brick, ceramics, JB Weld cast aluminum, and more. The epoxy is national sanitation foundation (NSF) certified and is safe to use in contact with potable water.

- A steel reinforced epoxy putty stick

- Easy to use and works on multiple metal surfaces

- Extremely durable 900 PSI strength

- Can be sanded, molded, painted, and drilled

- Dries quickly

- Can endure high temperatures

- Easy to use

- Strong, with a 900 PSI

- May not bond all that well with stainless steel

Most Versatile Aluminum Epoxy: J-B WELD KwikWeld Steel Reinforced Epoxy

The KwikWeld Professional Size Steel Reinforced Epoxy comes in five-ounce tubes and will set quickly in six minutes. The bond is long-lasting and durable and can be used on many surfaces. This epoxy is perfect for any of those do-it-yourself-projects. The epoxy will bond to metal, wood, fiberglass, ceramics, plastic, and more. The epoxy forms an extremely strong bond, measured at 3127 PSI.

The epoxy can also withstand high temperatures up to 230 degrees Fahrenheit (110 degrees Celsius) once it has cured fully. All you have to do is mix the two components in a 1:1 ratio, wait six minutes for it to dry, and four to six hours to fully cure. The cured epoxy appears dark gray. Also, once it has cured, the epoxy can be sanded, molded, drilled, filled, and tapped.

- Forms a permanent bond that can be shaped, sanded, and drilled

- Sets in 4-6 hours, full cure at 15-24 hours at room temperature

- Can withstand temperatures up to 550ºF when fully cured

- Forms a strong bond

- Quickly dries and cures

- Can withstand high temperatures

- Easy to work with

- Can be drilled, molded, painted, and sanded

- Bonds to a variety of surfaces

- You may experience an unpleasant odor

- The product is a skin irritant

- It may not be as strong as indicated

Best Easy Application Aluminum Epoxy: GORILLA Two-Part Epoxy

When many epoxy products come in two separate tubes or containers, the Gorilla two-part epoxy comes in a convenient syringe design that houses two separate compartments for the resin and hardener. All you have to do is depress the syringe and the two components are released in equal amounts.

The epoxy forms a strong and permanent bond that will dry in six minutes, so you have enough time to make repairs or reposition items. The tensile strength for this epoxy is 3.300 PSI. The epoxy can be used on a variety of surfaces including metal, plastic, ceramic, glass, and wood. Perfect for repairs around the homes that need a durable bond. The epoxy can help to repair, fill gaps, and is solvent resistant. Once dry, the epoxy is clear and provides a nice finish on anything that is exposed.

- Strong, permanent, fast, and gap-filling; great for multiple surfaces

- For tough repairs needing a durable bond and solvent resistance

- Dries clear and sets within 6 minutes, allowing for repositioning

- Fast curing, permanent bond

- Can be applied to many surfaces

- Easy application

- Dries clear

- Solvent resistant

- The product may only provide a single application

How to Use Aluminum Repair Epoxy

In most cases, a simple repair job using epoxy is not very difficult. The bigger or more complicated repair jobs might need a professional touch. However, when doing quick do-it-yourself repairs, all you need to do is to choose the epoxy that is best suited for your project, and make sure to follow any safety guidelines.

Depending on what epoxy product you are using, in most cases, you will need to combine two parts, the resin, and hardener. The instructions on what ratios to use are usually found on the container, but generally, it is a 1:1 ratio. There are syringe-type products that help to dispense the two components equally.

You will need to mix the two components, either with a mixing tool or stick. In the case of the epoxy putty, you can easily mix and knead the two components together. You can then apply to the aluminum surface that needs repairs. Application can be with a brush or stick for the liquid epoxy, while the putty can be applied with your fingers.

Preparing Aluminum for a Stronger Epoxy Bond

Preparing your aluminum surface will help to form a stronger bond and this will, in turn, make sure your repair job lasts for many years to come. The first step is always important, as some surfaces may contain greasy substances. You can use a solvent like mineral spirits, acetone, or another degreaser to wipe or spray down your metal surfaces. There are also water-based degreasers available if you do not wish to use a smelly solvent. Let us look at what the next steps are for creating a stronger bond to an aluminum surface.

- The next step is to use abrasion, which you can do with some sandpaper to make the surface rough. The rough surface will give more of a grip for the epoxy to adhere to.

- Clean and etch the surface with an eco-friendly citric acid, or you can also use a more abrasive acid solution like sulfuric acid, but this must be used with caution.

- In place of this step, you can also use a pre-treatment aluminum primer

- Rinse the surface with deionized water and then you can go ahead and prepare your epoxy components.

- Apply the epoxy according to the instructions provided.

Safety Guide When Using Aluminum Epoxy

When working with chemicals or any hazardous materials, it is best to follow the prescribed safety protocols. Many of the epoxy products can produce harmful fumes and can irritate if it gets onto any exposed skin. The fumes can not only be breathed in but may also irritate the eyes. Some products may say that they are non-toxic, but it is always better to be careful. Also, it is a good idea to always follow, and instructions written on the product itself. The following are the basic steps for keeping safe when working with epoxy resin.

- Wear gloves

- Use a mask, or consider a respirator

- Make sure to also wear eye protection

- You can also wear long sleeves or a coverall

- Work in a space that has enough air circulation

- You can use fans if necessary

- Try to work outside if possible

Tips and Tricks When Using Aluminum Repair Epoxy

Working with epoxy for the first time may be a bit daunting, but if all instructions are followed, the entire process should be easy and safe to complete. Here are a few tricks and tips when using aluminum epoxy.

- When mixing small amounts of epoxy, you can use an aluminum can. Turn it around and use the concave base as your mixing surface. When you are finished, let whatever is leftover dry and simply peel off, and you can then reuse the can.

- Having some paper cups around when mixing epoxy can be useful. The cups are not only good for mixing epoxy but can also be used to keep small items in or hold paint for small jobs.

- Guitar picks can work nicely for applying epoxy putty to small holes and scraping it even.

- Craft sticks also come in handy for stirring and applying the epoxy. They can all be used to scrape epoxy over small holes.

- Always measure your epoxy in exact amounts to avoid problems with bonding.

- Make sure to prepare and clean and degrease surfaces before bonding with epoxy.

- If you are bonding two surfaces, you can use clamps or a similar idea to keep the two items firmly together while the epoxy dries and hardens.

When working with aluminum epoxy for repairs, make sure to choose the proper product for the job. There are also other types of glue you can use to bond or repair aluminum, but aluminum repair epoxy is the best option for the strongest bond.

Frequently Asked Questions

Can You Apply Epoxy to Different Surfaces?

Yes, there are epoxy products that can be used on multiple surfaces including aluminum, and other metal surfaces as well as surfaces like plastic, ceramics, wood, brick, fiberglass, and much more. Always read the information provided with the epoxy product to see what surfaces are appropriate.

Must the Aluminum Surface Be Prepared Before Applying the Epoxy?

It is not necessary to prepare the surface before applying the epoxy. However, to create a stronger and more durable bond, preparation is key. You will need to degrease and clean the surface first, then use sandpaper to roughen up the surface, wipe clean again, before applying the epoxy.

What Are Some Popular Brands for Epoxy Adhesive?

There are many products on the market today, and it can be quite difficult to choose the right one for your project. The most well-known and popular epoxy products include J-B Weld, Loctite, and Gorilla.

Does JB Weld Work on Aluminum?

Yes, JB Weld aluminum is a popular product for use on metals and other surfaces.

Does Aluminum Epoxy Take Long to Dry?

Depending on the epoxy you choose, it can be quick-drying from five to ten minutes and fully cured in anything from 30 minutes to 24 hours. The best thing to do would be to read the product directions to find out drying and curing times.